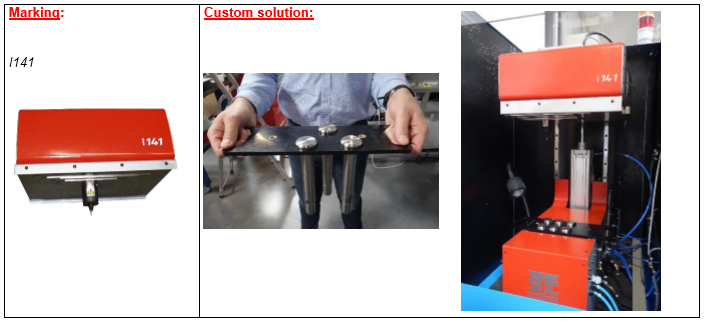

Circular marking on screw heads

Customer's need

Design and production of a system that can achieve automatic serial marking on screws of different head diameters. Part loading and unloading will be made manually using removable trays. The trays are adapted to the diameter of each screw.

Customer requirements:

- A system for a quick and convenient changeover: 15 min max

- A secure workspace to load and unload parts

- A system that integrates perfectly the machine’s working area and its safety (opening switch, safety light curtain, etc.).

Advantages/ Summary

The system is a dot peen i141 autosensing marking machine. It uses a 50 mm motorized axis mounted on a pneumatic actuator that allows time saving of the marking head’s setting. The operator loads the screws on an adjusted tray and charges the machine. The screws are maintained by a pneumatic clamping. Once the marking is done the operator can unload safely and repeat.

Solution

- Marking complying with aeronautical standards

- Circular marking of the product reference on the screw’s head

- Dot peen marking

English

English Français

Français 简体中文

简体中文