E-TOUCH MARKING SYSTEM

ULTRA MOBILE

The lightest and most compact portable in the world!

TOUCH SCREEN

User-friendly icon-based programming

FUNCTIONAL

Interchangeable front plates via a new magnet system

ALL IN ONE

Embedded controller

Presentation

Portable

Dot peen

Alphanumeric

2D datamatrix code

Logo

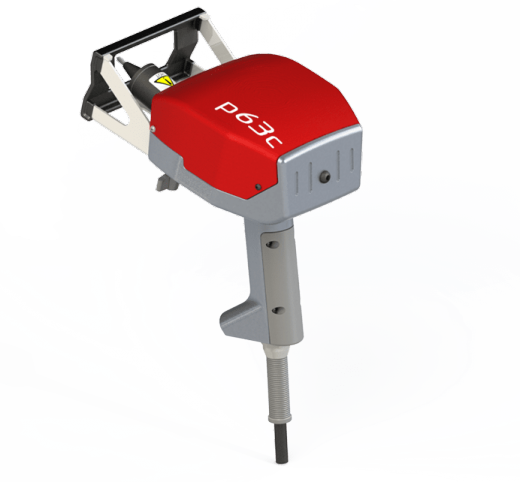

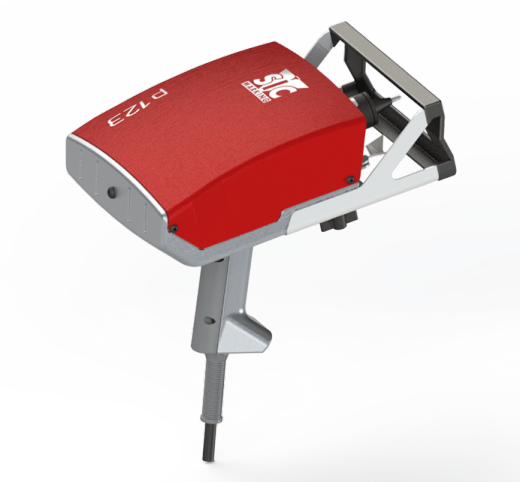

THE LIGHTEST AND MOST COMPACT PORTABLE ON THE MARKET

The e-touch portable marking system allows the identification of parts using dot peen technology. This process ensures reliable and unalterable marking directly into the material. The marking (text, logo, 2D Data Matrix code and QR Code) is defined by a succession of dots produced by a tungsten carbide stylus mounted in an electromagnetic striker assembly.

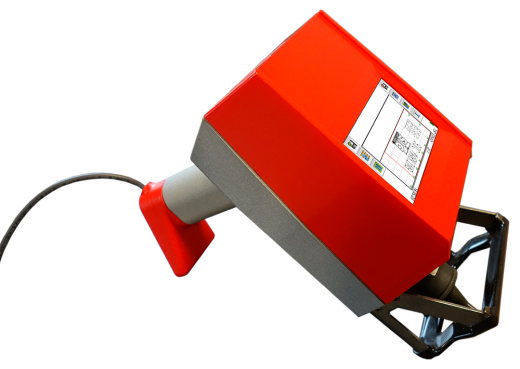

AN OPTIMISED TOUCH SCREEN

The e-touch incorporates a colour touch screen that offers user-friendly icon-based programming. The ergonomic and fluid interface allows two-handed programming just like a smartphone. Its touch screen can also be used with or without gloves, making it perfectly suited for use in an industrial environment. The SEE&MARK function, a 1:1 full scale viewing window, allows you to preview the marking exactly as it will be applied to the part.

EVER LIGHTER AND MORE COMPACT

The e-touch integrates its controller and touch screen and does not require an additional case to carry. Weighing less than 2kg and with a small footprint of 220 x 210 x 125mm, the e-touch is the most compact and lightweight dot peen marking portable on the market. Nevertheless, it is very robust and rigid thanks to its internal metal structure. In addition, it has an ergonomic handle and an excellent weight balance, offering outstanding manoeuvrability.

A REVOLUTIONARY INTERCHANGEABLE FRONT PLATE SYSTEM

The e-touch has 3 front plates that allow it to adapt to the numerous marking configurations. The standard front plate, specially designed for marking flat parts or cylinders. The magnetic front plate is perfectly adapted to the marking of metal parts.

Finally, the adjustable reduced front plate can be used for marking small parts, recesses or difficult to access areas. The versatility offered by these 3 different front plates allows it to mark a large majority of customer parts without the need for a column, which often proves to be cumbersome and impractical when you are looking for the mobility of a portable system.

The great novelty of the front plate is their fixing system. This is done using a magnetic system that is unique on the market and allows you to change from one side to the other very quickly.

Mechanic features

|

Marking Window: |

60 x 25 mm |

|

Dimensions: |

210 x 125 x 220 mm |

|

Weight: |

1.9 kg |

|

Robotic Cable: |

5m |

|

Stylus: |

Carbide |

Electronic features

|

HD Color Screen: |

95 x 55 mm |

|

Keyboard: |

Tactile |

|

Power: |

100W |

|

Supply: |

100 to 240 VAC, 50/60 Hz |

Steering software

The e1 integrated controller software is used to program all parameters directly through the keyboard (autonomous operation). A Windows tool library also allows programming from a PC.

|

Marking Files: |

Up to 20,000 |

|

Memory: |

100 Mb |

|

Variable: |

Alphanumerical, Serial, Date, Barcode, and Logos |

|

Marking Files: |

Upload/Download From a USB Key |

|

Fonts: |

Courier, 4 x 6, OCR-Bold, OCRA, and OCR |

|

Marking Type: |

Linear, Radial, Angular, Datamatrix, and Logo |

|

Speed: |

Up to 2.5 Characters per Second |

|

Character size: |

1 mm (minimum) |

|

Impact Force: |

1 - 9 Levels |

|

Depth: |

Up to 0.3 mm |

|

Resolution Between Dots: |

0.05 mm |

COMMUNICATIONS

|

Ports |

USB and Jack |

Options

English

English Français

Français 简体中文

简体中文