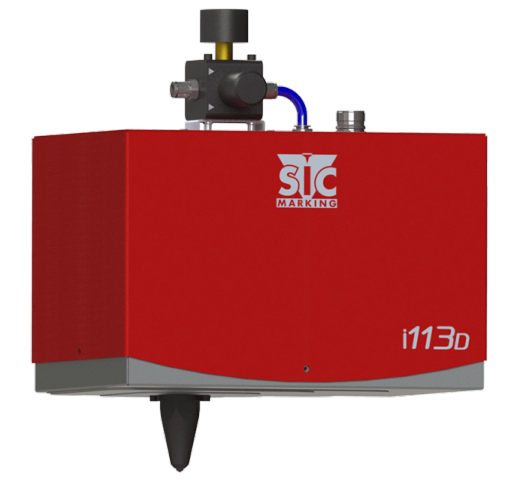

e10R i113d Deep marking system

Deep marking

Custom stylus dedicated to deep marking

Fast marking on all types of surfaces

Powerful mechanics and controller

Simple and easy to use

Ideal for integrations

Low acquisition cost

Quick and simplified preventive maintenance

Presentation

Integrated

Dot peen

Alphanumeric

2D datamatrix code

Logo

Robust integrated marking head

The i113d marking head is easily integrated on automated lines in industrial environments. Its ease of use makes it possible to mark parts of different shapes, surfaces and materials. It produces rapidly a deep mark (up to 0.8 mm on standard steel) using dot peen technology on all types of materials. The speed and power of the integrated software makes it a high performance engraving system.

Mechanic features

| Marking Window: |

110 x 60 mm |

|

Weight: |

17.5 kg |

|

Connecting Cable: |

5m, up to 10/15m optional |

|

Stylus: |

Carbide diameter 6 dedicated to deep marking |

|

Air supply: |

6 bars |

Electronic features

Optimized for flawless integration on automated production lines, the e10 R controller has a sealed membrane keyboard and 480 x 272 pixels backlit LCD color screen, providing the operator with a direct and easy-to-use interface. It is equipped with an innovative microprocessor that offers immediate start up and smooth browsing, and its comprehensive software suite allows for linear, angular, radial, and mirror image marking. An optional 3rd/4th axis circuit board can be installed to control a motorized column and/or rotary axis. Self-diagnostic and machine history functions are also included.

The e10 R can be mounted vertically in an electrical cabinet with a DIN rail mounting kit (optional). A fully enclosed steel exterior protects the internal components, allowing use in even the most critical industrial environments.

|

Dimensions: |

112 x 380 x 222 mm |

|

Weight: |

5 kg |

|

LCD Screen Resolution: |

480x272 p. |

|

Keyboard: |

QWERTY-Integrated with Membrane Overlay |

|

Power: |

300 watt |

|

Power Supply: |

Single Phase (85 to 260VAC, 50-60Hz) |

|

Number of Controlled Axes: |

2 (3 and 4 available as options) |

|

Card Options: |

Booster (deep marking) and Ethernet (communication) |

|

USB Port: |

Transfer of Marking Files |

Steering software

|

Marking Files: |

More than 2000 |

|

Memory: |

7110 Ko |

|

Alphanumeric Characters: |

Serial Number, Date Coding |

|

Logos: |

Create and Edit using PC Software |

|

Datamatrix: |

Up to 348 Characters (48 x 48 dots) |

|

Fonts: |

Arial, Courier, OCR, OCRA |

|

Style: |

Angular, Radial, Inverse, Mirror |

|

Speed: |

Up to 5 Characters per Second |

|

Character Size: |

0.1 mm to 99 mm |

|

Impact Force: |

9 Adjustable Levels |

|

Depth: |

Up to 0.5 mm |

|

Resolution Between Dots: |

0.05 mm |

|

Maximum Stylus Stroke: |

Up to 8 mm |

|

Work Shift Management: |

10 shifts |

|

Password Protection: |

3 Security Levels |

|

Historical Function: |

Available by Password |

|

Maintenance Assistance: |

Auto-diagnostic Component |

|

Languages Available |

17 |

COMMUNICATION

|

Ports: |

RS232, RS422, USBx2, RS485 Profibus, and Ethernet Optional Board |

|

Inputs/Outputs: |

16 |

|

External Keyboard Input: |

USB |

|

External Output: |

5V-0.5A and 24V-0.5A |

|

Logos: |

Creation and Transfer Software |

|

Files Backup on PC: |

USB Key for Transfer |

|

Database Link: |

Optional |

Options

See also

English

English Français

Français 简体中文

简体中文