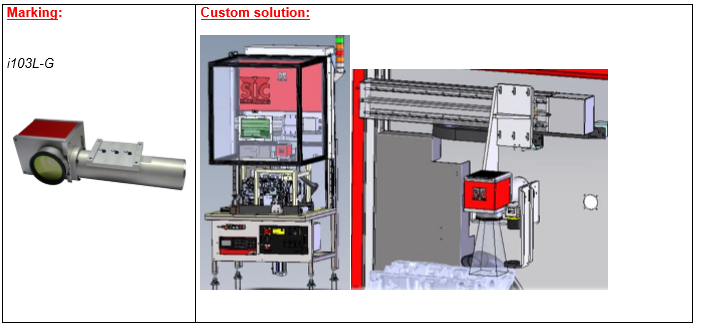

Laser marking on bearing caps

Customer's need

The customer would like to have a laser marking system to mark five bearing caps with one number from 1 to 5. These numbers will then be read.

The entire part weighs 50 kg, for a footprint of 410 x 260 x 370 millimeters. The system must have a complete carterisation and should comply with the current regulations concerning the use of Class 4 lasers.

The system should read the elements once marked to validate the marking. If a part is non-compliant, the system will go into default and inform the operator via a non-compliance light indicator on the button box. The part will then be moved away from the normal flow.

The marking pace will be relatively important.

Advantages/ Summary

The system consists of an integrated i103 L-G laser with a camera. The system is integrated in a production line controlled by a PLC requiring use of field buses (Profibus). The laser is mounted on a digital Z-axis.

Solution

- Data matrix laser marking

English

English Français

Français 简体中文

简体中文