Laser marking station for engine crankcases

Customer's need

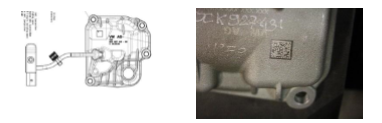

The customer would like to mark a series of parts (aluminium smelter card) with the most automated station possible to optimize productivity. On parts, there will be an alphanumeric marking and a datamatrix code, which will be read to supply a database. Also, the customer would like the system to operate an electrical continuity test. The maximum cycle time is 15 seconds or less which leaves 7 seconds to mark.

Advantages/ Summary

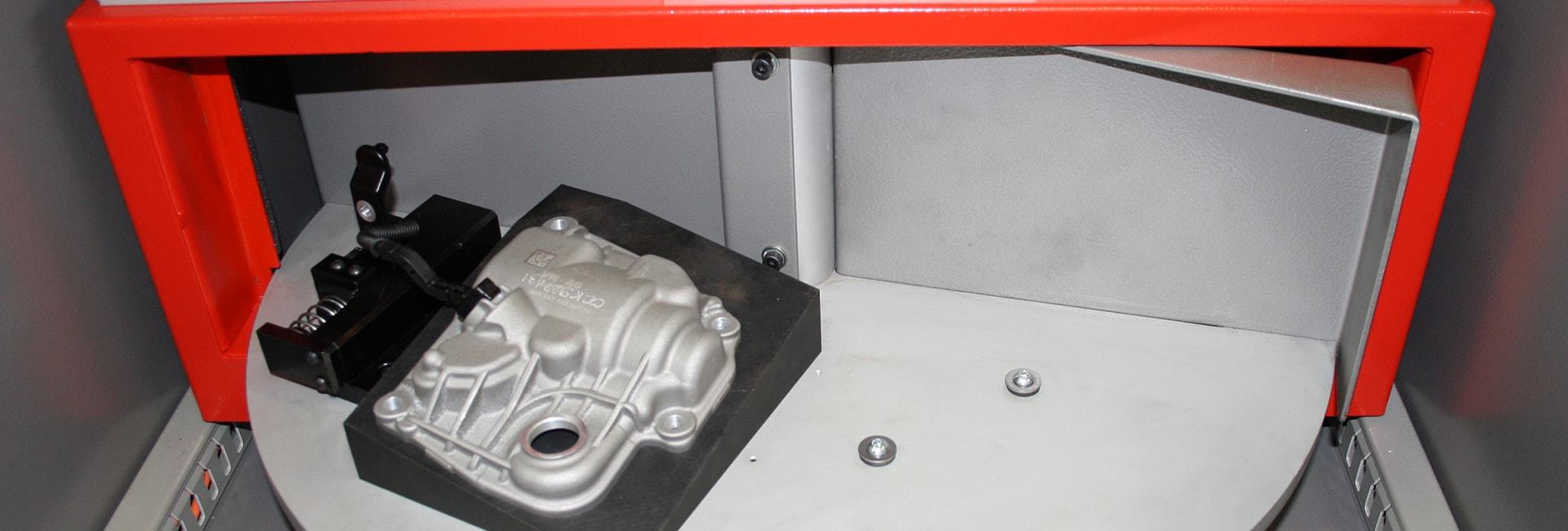

The system is composed of an i103L-G laser integrated in a XL Box.

Machine cycle: The operator places the part on the holder, the plate rotates 180 °, the continuity test and the marking are performed. Then, a camera placed under the galvanometric head reads the datamatrix code. Meanwhile the operator has loaded a new part. When the plate rotates a second time, this new part goes in to be marked and the already marked part is retrieved by the operator.

Solution

English

English Français

Français 简体中文

简体中文