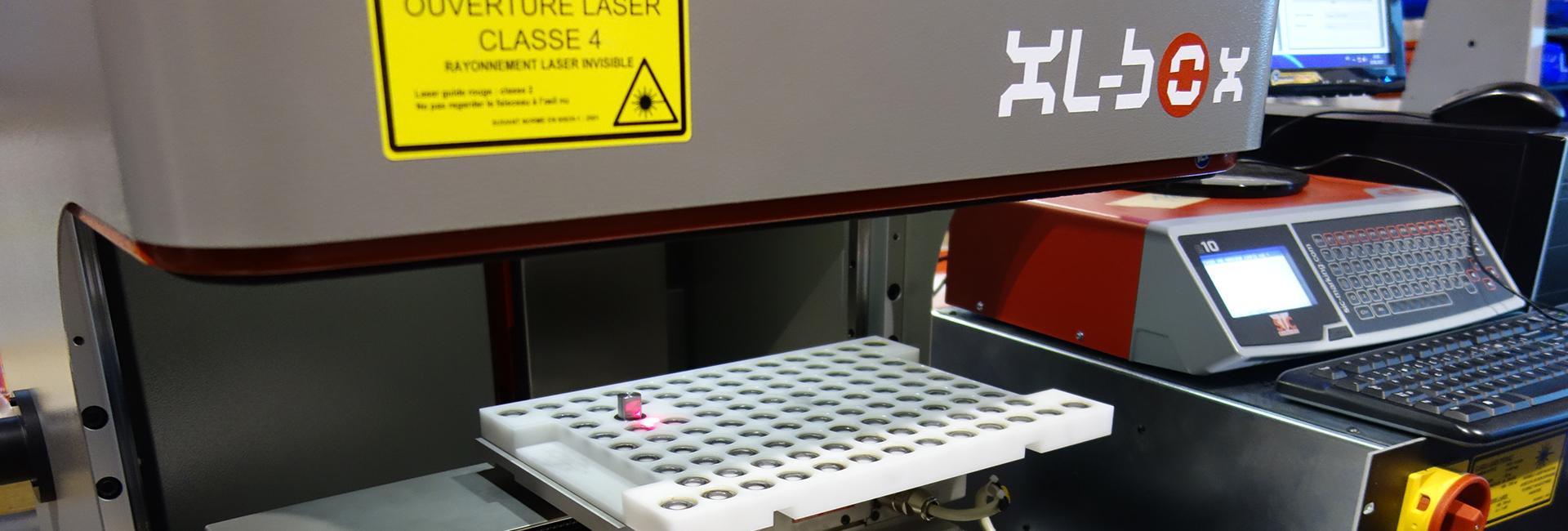

Laser marking system with 4 axes

Application

The customer would like to adapt the XL Box laser station to mark different size parts using trays while maintaining the possibility of standard marking.

Engraving solution

The standard mode of the marking system makes it possible to mark cylindrical parts using a D-axis. The trays with the parts to be marked are managed by three axes (X, Y, Z). A specific software allows the recovery of data to be marked on the customer's ERP. A file is generated by pressing a button in the application. The information retrieved is as follows:

• Serial number: linked to an OF, identical for all OF parts

• Batch number

• Timestamp

• Serialization: one number per part, concerns 1% of the production

As soon as the file is updated, a laser marking file is automatically loaded. The specific software can only be used with the trays. SIC LASER ADVANCE software allows to manage the products to be marked on the rotary axis (D-axis) or on the bottom plate of the XL-Box.

The operator places the tray with the parts to be marked. He selects the "tray" mode and launches the marking cycle. At the end of the marking cycle the operator repositions the tray in order to mark the following parts.

Result

- Laser marking using trays and standard marking

- Cylindrical parts of small volume (max 230 mm) and different sizes

- Alphanumeric marking

- Compliance with aeronautical standards

English

English Français

Français 简体中文

简体中文