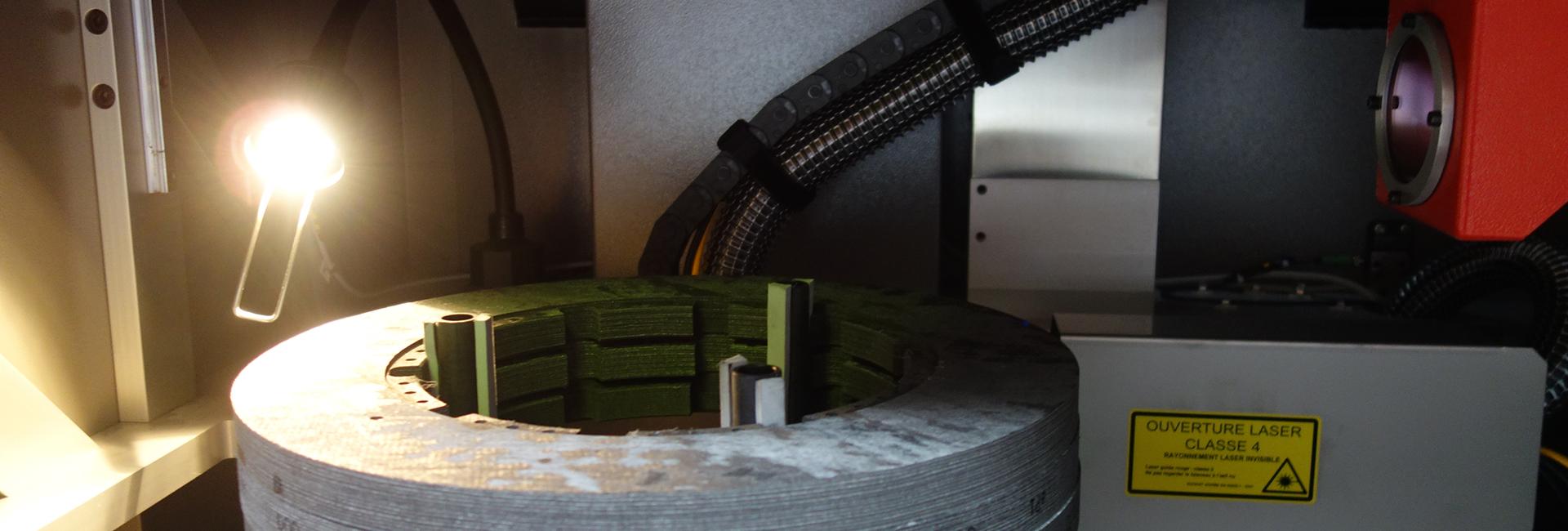

Laser marking system for carbon brake disc

Application

The customer would like to mark product references, part numbers, variables on different brake discs. The goal is to mark several parts in one machine cycle, with a simplified operator interface.

Marking solution

The system is custom laser marking machine (50W) installed on a chassis with a laser control rack, an industrial PC, a button box, and a screen mounted on a supporting arm.

The operator, through the software, launches the production order. The door closes automatically and the data are registered in the marking file variables. The laser is mounted on an X-Y table that allows the laser head to move towards 1 to 3 identical products and mark them on the inside. The D-axis is useful to mark on the contour of discs. The special feature of this application is the 90 ° angle of the laser, using a specific mirror.

The custom software installed on the PC includes a graphical representation of the products to be marked and allows to:

- enter the variable data fields manually or scan a barcode by using a barcode reader

- display a preview of the file

- open and close automatically the door after marking

Result

- Laser marking of alphanumeric and datamatrix codes

- Marking in Inner and outer diameter, depending on the product range : 115 types of parts and 14 variables

- Height of characters : from 5 to 7 mm (width of characters : proportional to height)

- Depth of marking : 0.20 mm minimum to 1mm maximum

- Custom software for code reading

Advantages

- No consumable and no production time lost due to tool change.

- With laser, the marking quality and depth are repeatable over the time.

- No rework operation and/or scrapping of parts with laser marking.

- The laser solution is more flexible: engraving data’s are automatically charged from an Excel sheet and generated by an ERP (no manual failure, no time waste).

- In compliance with aeronautical standards

English

English Français

Français 简体中文

简体中文