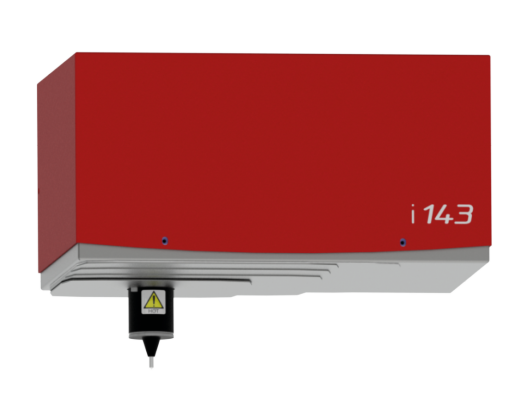

e10 R i83 Dot peen Marking Head

Precise, Efficient Marking

Efficient components, and a powerful controller software

High Performance

High speed, high stylus-to-part distance variation tolerance, powerful integrated software

Simple and User-Friendly

Clear-cut integration and programming

Robust Reliability

Designed for intense use in industrial environments

Presentation

Integrated

Dot peen

Alphanumeric

2D datamatrix code

Logo

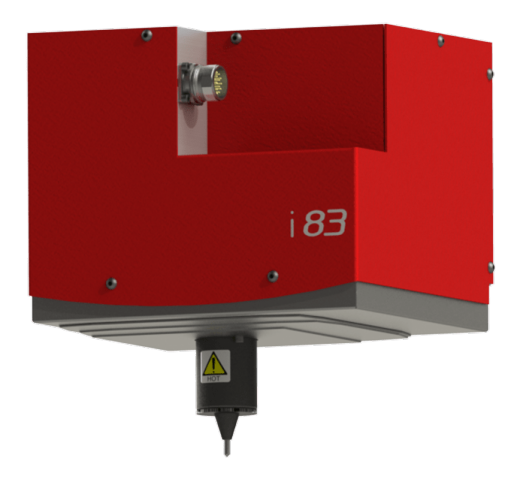

INTEGRATED DOT PEEN MARKING HEAD

The integrated marking solution i83 was specifically engineered to integrate seamlessly into automated production lines. Easy to operate, it automatically detects the marking surface enabling rapid dot peen marking on components of various shapes, sizes, and surface materials. In addition to marking plastics and hardened steel (up to 62HRC), its unique electromagnetic driving technology does not require a separate pneumatic system.

Known for its rugged reliability, the integrated marking system i83 is a high-performance tool that requires minimal maintenance and no consumables. Its internal components are protected by a thick steel frame allowing intense industrial operation, even in the roughest environments. The cable is easily removable for fast and easy replacement when necessary.

The high speed integrated software and user friendly programming process makes the i83 simple for anyone to use, with minimal training. Effortless operation is enhanced by the quality and accuracy of the guidance and the wide tolerance between the stylus and the part, making the i83 a flawlessly reliable dot peen marking machine.

Mechanic features

|

Marking Window: |

80 x 70 mm |

|

Dimensions: |

225 x 202 x 256 mm |

|

Weight: |

9.4 kg (20.7 lbs.) |

|

Connecting Cable: |

5m (up to 15m available) |

|

Stylus |

60 mm Carbide |

|

Protective Bellows: |

Steel |

|

Automatic Z-Axis: |

Optional auto-sensing function (i83A) |

Electronic features

The e10 R Controller offers seamless integration into automated production lines. A fully enclosed steel cabinet shelters the internal components, permitting use in even the most intensive industrial environments. Using a DIN rail mounting kit (optional), the e10 R can be mounted vertically in an electrical cabinet for stationary operation.

The e10 R boasts a revolutionary microprocessor that offers a swift set-up process and smooth browsing. Its sealed QWERTY keyboard and LCD color screen provide the operator with a user friendly interface that is shielded from the workspace elements. The e10 R controller is ideally suited for controlling integrated marking heads, since the marking files can be both created and edited directly on the machine using the controller interface. Its comprehensive software package allows for a range of marking types, including linear, angular, radial, and mirror image marking. An optional 3rd/4rth axis circuit board can be installed to control a motorized column and/or rotary axis. Self-diagnostic and machine history functions are also included.

|

Dimensions: |

112 x 380 x 222 mm |

|

Weight: |

5 kg (11 lbs.) |

|

LCD Screen Resolution: |

480 x 272 Pixels. |

|

Keyboard: |

QWERTY-integrated with membrane overlay |

|

Power: |

300 watt |

|

Power Supply: |

single phase, 85 to 260VAC, 50-60Hz |

|

Number of Controlled Axis: |

2 (also available with 3 or 4) |

|

Card Options: |

Booster (deep marking) and Ethernet (communication) |

|

USB Port: |

Transfer of marking files |

Steering software

|

Marking Files: |

More than 2000 |

|

Memory: |

7110 Ko |

|

Alphanumeric Characters: |

Serial number, date coding |

|

Logos: |

Creation/Editing from PC software |

|

Datamatrix: |

Up to 348 characters, 48 x 48 dots |

|

Fonts: |

Arial, Courier, OCR, and OCRA |

|

Style: |

Angular, radial, inverse, mirror |

|

Speed |

Up to 5 characters per second |

|

Character Size: |

0.1 mm to 99 mm |

|

Impact Force: |

9 adjustable levels |

|

Depth |

Up to 0.5 mm |

|

Resolution Between Dots: |

0.05 mm |

|

Maximum Stylus Stroke: |

Up to 8 mm |

|

Work Shift Management: |

10 shifts |

|

Password Protection: |

3 security levels |

|

Historical Function: |

Available by password |

|

Maintenance Assistance: |

Auto diagnostic component |

|

Languages Available: |

17 |

COMMUNICATIONS

|

Ports: |

RS232,RS422, USBx2, RS485 Profibus, and Ethernet optional board |

|

Inputs/Outputs: |

16 |

|

External Keyboard Input: |

USB |

|

External Output: |

5V-0.5A and 24V-0.5A |

|

Logos: |

Creation and transfer software |

|

File Backup: |

USB key for transfer |

|

Database Link: |

Optional |

Options

English

English Français

Français 简体中文

简体中文