Datamatrix and Automated Vision Solutions

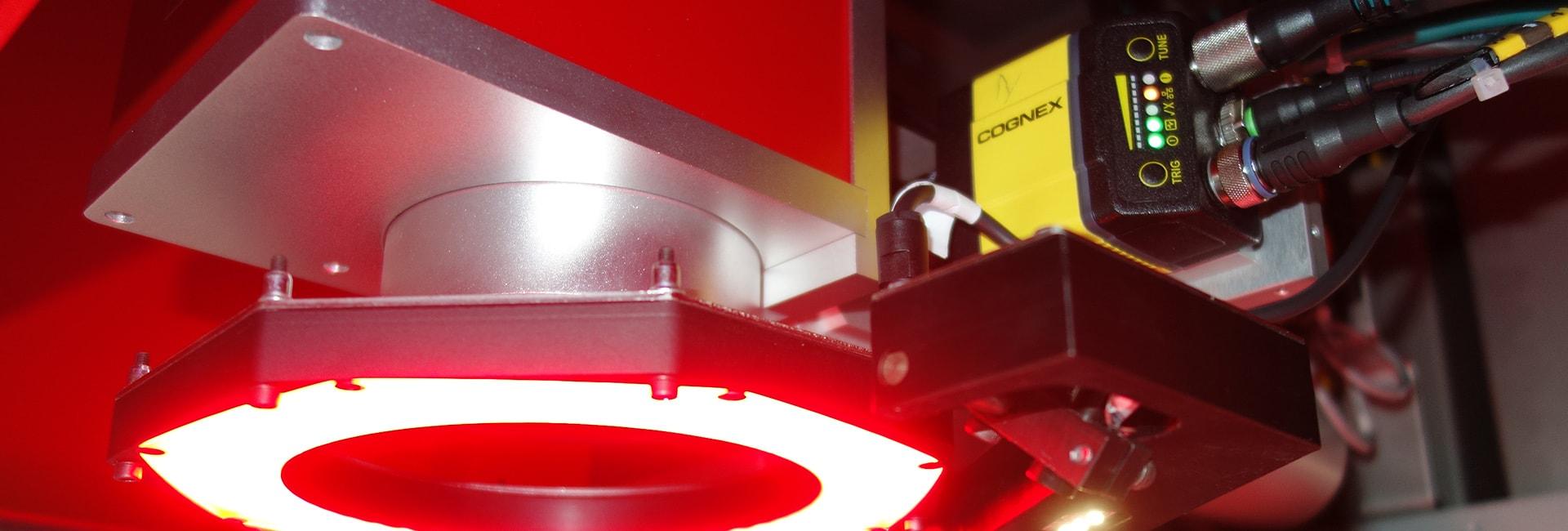

SIC Marking has developed a full “mark & check system” to offer a real traceability system. Vision systems could be integrated by adding a camera (including a decoder), a light system around the marking machine.

As soon as the datamatrix code is marked on the part surface, the next step consists of reading the code to approve its quality and readability. This test is important to determine whether the symbol is decodable or not. A camera (also called reader) with an integrated (or external) light source is required. For integrated on production lines, fixed-mount readers are used. They automatically detect the presence of the part to mark and then give the signal to start the "reading" action. These vision systems can be easily set up, viewed and maintained thanks to state-of-the-art communication features (for example Ethernet). Vision applications are usually customized solutions: SIC Marking possesses all the required equipment and expertise to provide a complete solution.

Datamatrix readability:

The term "readability" is commonly used in the traceability industry. A readability test will validate if the datamatrix code can be easily read by the vision system. Inadequate readability may require removal of part from the production line to analyze and research causes. A datamatrix code is constituted of several areas:

- Quiet zone

This is a clear area around the 2D code, which normally has a four (4) dot width; to the quiet zone reduces decoding algorithms defects. - Finder "L" pattern

This is an "L" formed by orthogonal lines that enables a good position of the code in the reader's field of view. A suitable location of the code within an image is the first step in successful reading. - Modules or cells area

Once the reader has found the code to be read, the 2D code image can be analyzed, by identifying light cells and dark cells. Datamatrix cells are decoded according several aspects like contrast, positioning, shape, size.

Datamatrix verification:

Once the datamatrix code was confirmed to be readable, the traceability process requires analysis of the symbol to enable feedback and comparison with ISO standards. A verification system will immediately detect a problem such as marking issues, part surface issues, or settings issues. Verification is done by the reader and software to compare with datamatrix quality metrics, defined by ISO 15415 or ISO 16022 standards. A grade is given, A is excellent and F is Fail. Software is used to store and analyze these grades.

The main issue in 2D marking applications lies with the selection and setting of the parameters that enhance the quality of the code. For this reason, SIC Marking has developed a comprehensive software which:

• Indicates which marking parameters should be changed to enhance marking quality,

• Stores all information relevant 2D quality information in a database,

• Produces reports on marking analysis,

• Helps provide diagnostic on marking quality.

The full traceability system prevents corrupted code and the presence of non-identifiable parts in your production process. According to your requirements, we can provide verification equipment based on existing standards (IAQG, ISO15415, and AS478) or on customized specifications with up to 10 criteria to be checked on the marked code.

SIC Marking traceability system: MRVC:

To guarantee the highest levels of quality and security with 2D codes, SIC Marking developed the MVRC process on its datamatrix engraving machines: MRVC for Mark, Read, Verify, and Communicate.

- Mark

Based on our experience and technology, SIC marking provides the most reliable marking systems on the market for 2D code marking applications.

- Verify

Compatible with all standards, the system checks the quality of the code against existing quality standards or predefined parameters, ensuring a high quality readable code.

- Read

The verified code can be read at all necessary process steps.

- Communicate

The machine communicates with a complete database managed by the software and is able to record marking data, images of marked codes and quality reports.

English

English Français

Français 简体中文

简体中文