Dot peen or Laser Datamatrix Marking

Compatible with several marking technology (dot peen & laser), this 2D code allows an automatic and secure identification with specific readers and algorithms.

A traceability process is based on several steps: marking, reading, verification, communication. The primary methods used to produce machine-readable symbol, such as Datamatrix or Barcodes, include dot-peening and laser marking.

Dot peen marking:

Dot peening is achieved by electromechanically striking a carbide stylus against the surface to be marked. The quality of the dots created indenting the material is very important for the readability of the code. SIC Marking has developed a wide range of high reliability dot-peen datamatrix engraving machines. Dot peen technology has the best quality/price ratio. Dot size, shape and spacing can be controlled over time thanks to a robust mechanical system (X and Y axis) and a routine maintenance of the dot marker. In some cases, the application may require further preparation of the part surface (treatment, machining...) in order to improve overall readability of the code. Dot peening was first widely used in the automotive and aerospace industries, and is now standard in many industries.

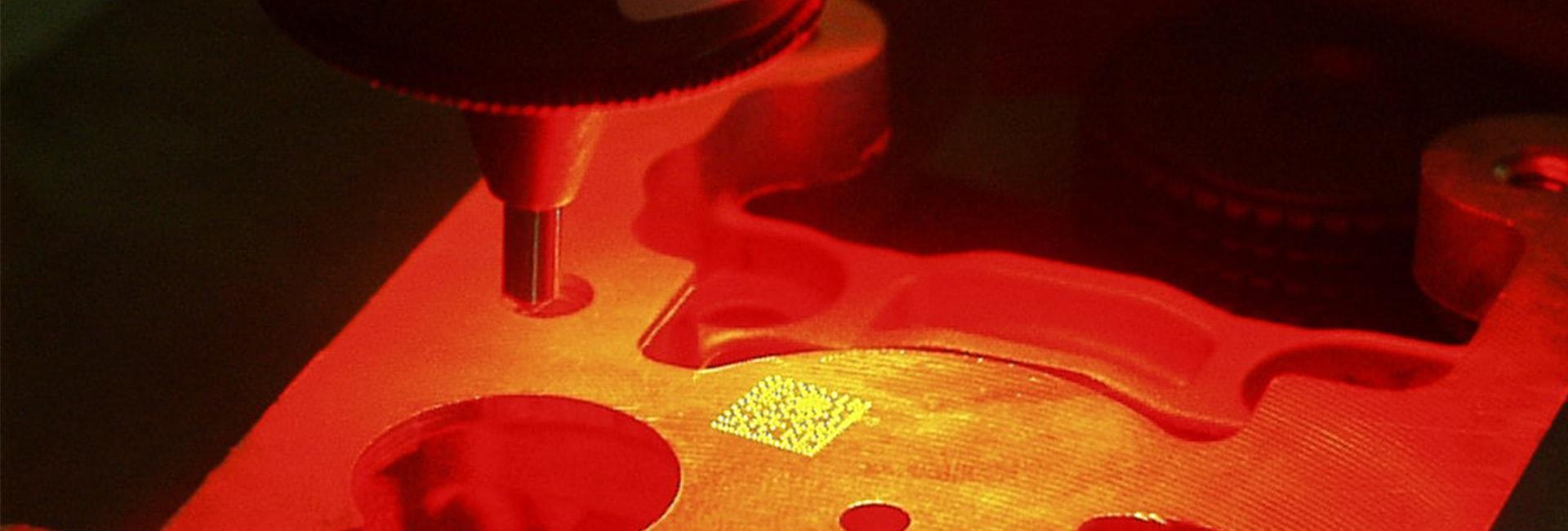

Laser marking:

Laser marking is one of the most performant technologies for direct part marking. The laser beam generates localized heating on the surface and creates a chemical alteration in order to mark or engrave. The resulting quality depends on the interaction of the laser with the material it is marking. The previous laser technology generations, such YAG or CO2, were efficient but costly to maintain. For this reason and many others, SIC Marking only uses the fiber laser technology in its datamatrix laser marking machines. This technology offers high speed and consistency, with very high precision marking. SIC Marking lasers can rapidly produce a high definition datamatrix code in reduced area. Laser marking systems were set up in electronics, aerospace, and automotive industries, and are now widely used in many industries where high production and quality rates are required.

English

English Français

Français 简体中文

简体中文