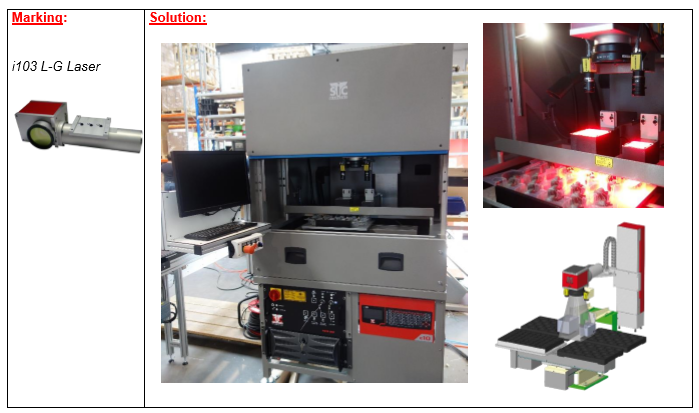

Laser station for the marking & reading of turbine wheels

Customer's need

For turbine production, the customer would like to improve its production line with a marking station for turbine wheels traceability. All turbine wheels should be marked with a data matrix code that will be read along the complete production line. Parts should be marked directly inside trays in order to reduce operator process and cycle time. Due to rough positioning of the turbine wheels in the trays, the laser station should adjust its marking position and read the data matrix codes for verification.

Advantages/ Summary

The operator puts the tray with the turbine wheels into the dedicated tooling and starts the marking cycle. The marking head adjusts its position and the first camera checks the diameter and location of the turbine wheel. Once the part is marked, a second camera checks that the data matrix code is correct according to the customer's marking quality assessment. If the code is approved the marking head moves to another turbine to mark. At the end of the cycle, the operator removes the tray with the marked turbine wheels.

Solution

- Laser marking on steel turbine wheels

- Marking and reading of data matrix codes

- Identification of the part’s diameter and position

- Checking of the marking quality of each data matrix code

English

English Français

Français 简体中文

简体中文