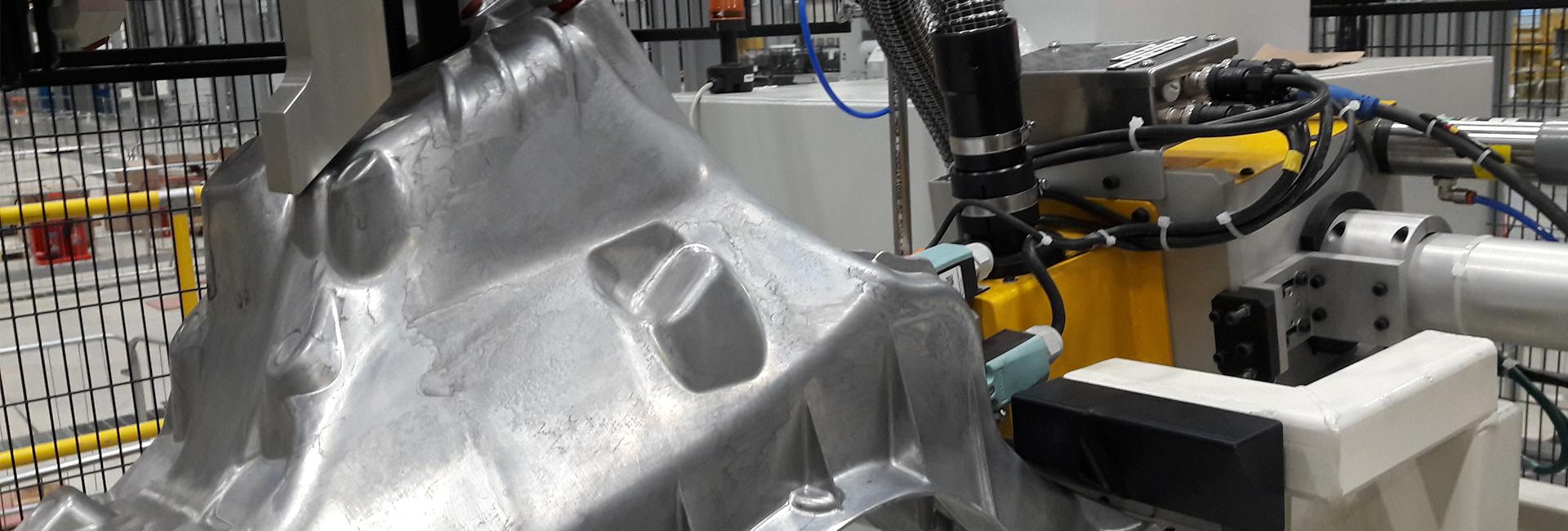

Laser marking on die cast part

Application

Our customer requested to mark datamatrix and alphanumeric codes on aluminum die cast parts during manufacturing process. The die cast is made of 2 parts that are collected by a robot (temperature 40°C), then cooled in a water tank, and finally brought to a trimming machine that separates them. A second robot takes both parts and brings them to the laser marking station.

Engraving solution

The marking system is made of a 50 W laser marking head mounted in a special enclosure (with A/C) and a vision system enclosed separately. The marking head is mounted on a welded painted frame. The laser and the vison systems are controlled by the PLC via Profibus. Safety is ensured by 6 detectors, 5 are mechanical and 1 is inductive. The welded painted frame holds up a laser control rack, a fume extractor, and a air cooler. All these devices are integrated directly on the manufacturing line.

Result

- Marking of a datamatrix + 14 alphanumeric characters

- Encoding = shift code, DCM id, date, die cast serial number

- Marking window : 170×170 mm

English

English Français

Français 简体中文

简体中文